Kugadzikana kwenguva refu kwemagineti kunetsekana nemushandisi wese.Kugadzikana kwesamarium cobalt (SmCo) magineti kwakakosha kune yavo yakaoma application nharaunda.Muna 2000, Chen[1]uye Liu[2]et al., dzidza kuumbwa uye chimiro chepamusoro-tembiricha SmCo, uye yakagadzira yakakwirira-tembiricha-inodzivirira samarium-cobalt magineti.Iyo yakanyanya tembiricha yekushandisa (Tmax) yeSmCo magineti yakawedzerwa kubva pa350°C kusvika pa550°C.Mushure meizvozvo, Chen et al.yakavandudza kuramba kweoxidation yeSmCo nekuisa nickel, aluminium uye mamwe machira paSmCo magineti.

Muna 2014, Dr. Mao Shoudong, muvambi we "MagnetPower", akanyatsoongorora kugadzikana kweSmCo pakupisa kwakanyanya, uye migumisiro yakabudiswa muJAP.[3].Migumisiro yacho ndeiyi:

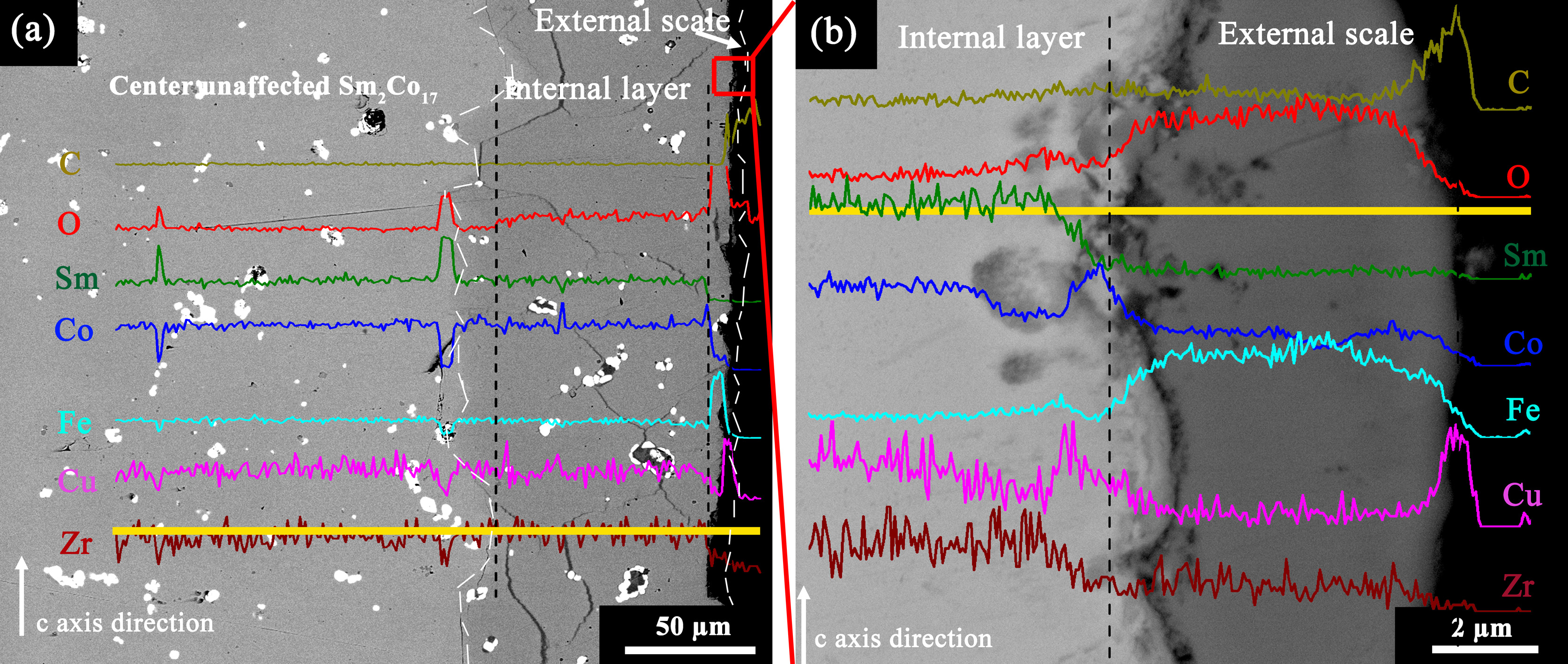

1. RiniSmCoiri munzvimbo yepamusoro-soro (500 ° C, mhepo), zviri nyore kuumba degradation layer pamusoro.Kusvibiswa kwepamusoro kunonyanya kuumbwa nechiyero chekunze (Samarium inopera) uye mukati memukati (yakawanda ye oxides).Iyo yakakosha chimiro cheSmCo magineti yakaparadzwa zvachose muiyo degradation layer.Sezvinoratidzwa Mufananidzo 1 uye Mufananidzo 2.

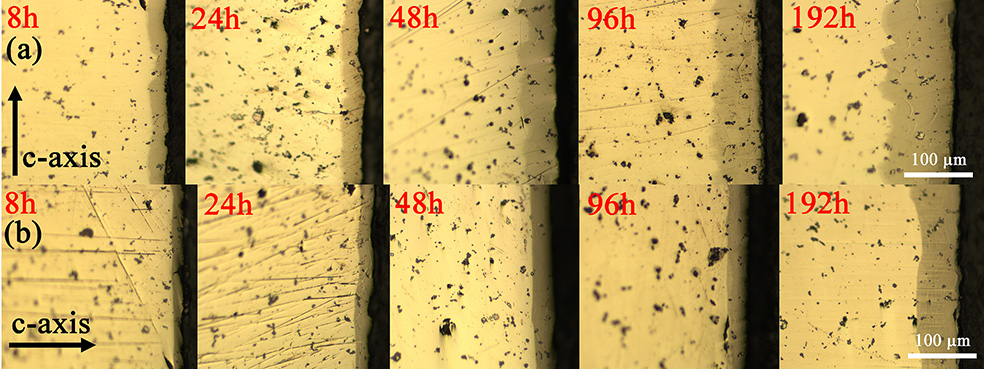

Fig.1.Iyo optical micrographs yeSm2Co17magineti isothermal inobatwa mumhepo pa500 ° C kwenguva dzakasiyana.Iyo yekushatisa maseru pasi penzvimbo ayo ari (a) parallel uye (b) perpendicular kune c-axis.

Fig.1.Iyo optical micrographs yeSm2Co17magineti isothermal inobatwa mumhepo pa500 ° C kwenguva dzakasiyana.Iyo yekushatisa maseru pasi penzvimbo ayo ari (a) parallel uye (b) perpendicular kune c-axis.

Fig.2.BSE micrograph uye EDS zvinhu mutsara-scan mhiri kweSm2Co17magineti isothermal inobatwa mumhepo pa500 ° C kwe192 h.

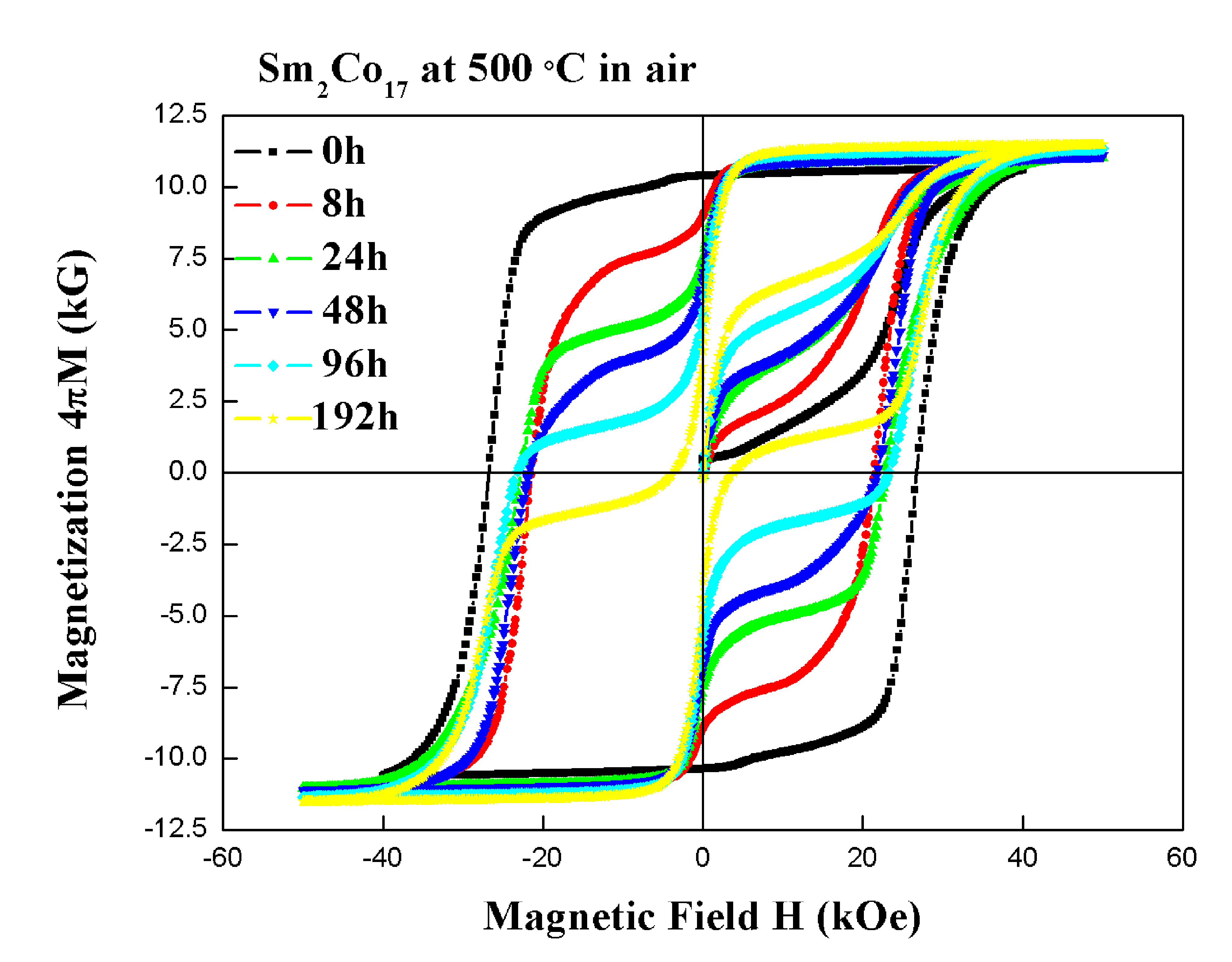

2. Iko kuumbwa kukuru kwekuparara kunobata zvakanyanya simba remagineti eSmCo, sezvinoratidzwa mumufananidzo 3. Mamiriro ekuora ainyanya kuumbwa neCo (Fe) yakasimba mhinduro, CoFe2O4, Sm2O3, uye ZrOx muzvikamu zvemukati uye Fe3O4, CoFe2O4, uye CuO muzvikero zvekunze.Iyo Co (Fe), CoFe2O4, uye Fe3O4 yakashanda seyakapfava magineti zvikamu zvichienzaniswa neyakaoma magineti chikamu chepakati chisina kubatwa magineti eSm2Co17.Hunhu hwekuzvidzikisira hunofanira kudzorwa.

Fig. 3. The magnetization curves of Sm2Co17magineti isothermal inobatwa mumhepo pa500 ° C kwenguva dzakasiyana.Kuyedza tembiricha yemagnetization curves ndeye 298 K. Iyo yekunze munda H inofananidzwa neiyo c-axis alignment yeSm.2Co17magineti.

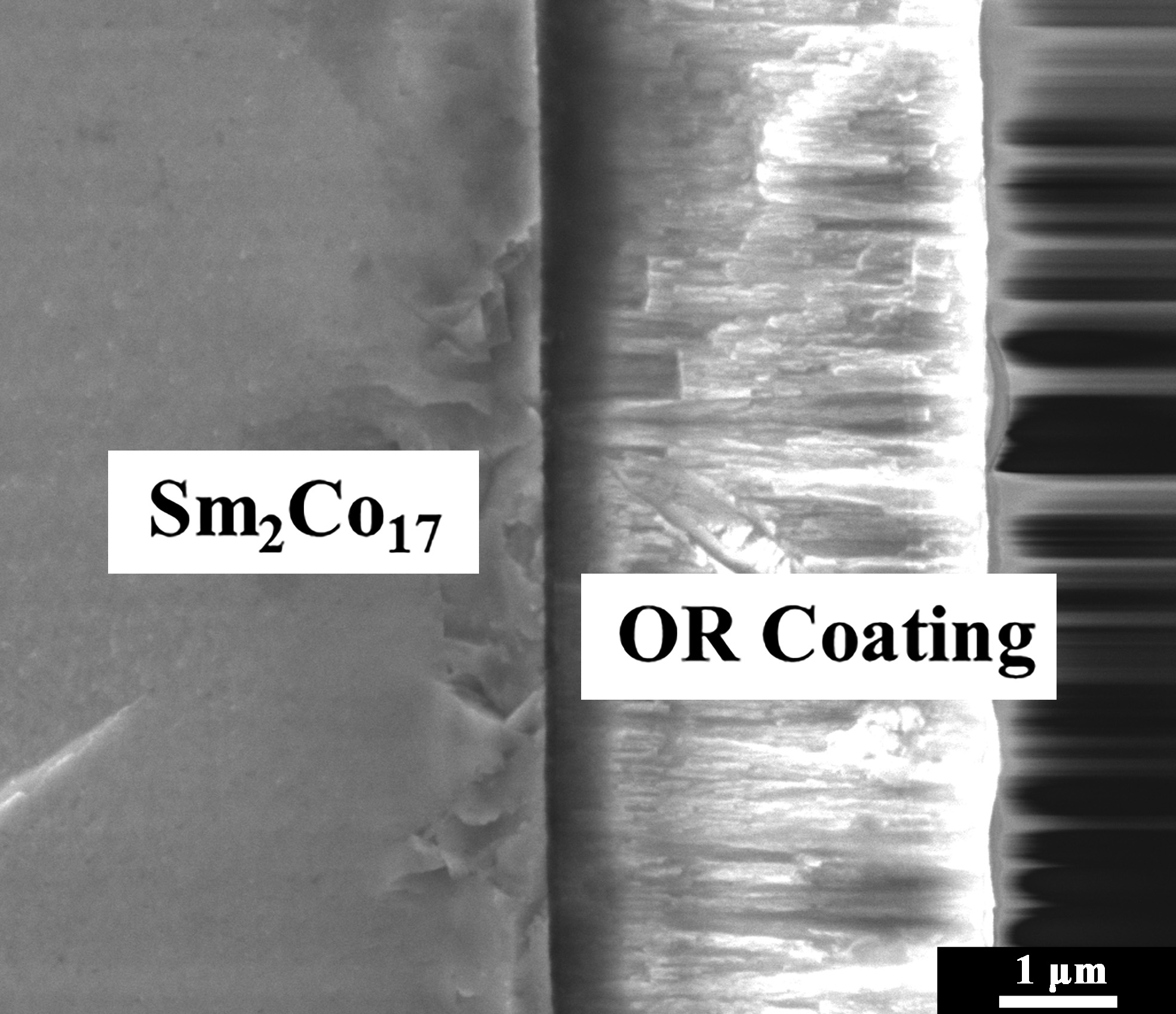

3. Kana mabhanhire ane high oxidation resistance akaiswa paSmCo kuti atore nzvimbo yepakutanga electroplating coatings, kusvibiswa kweSmCo kunogona kunyanya kudziviswa uye kugadzikana kweSmCo kunogona kuvandudzwa, sezvinoratidzwa mumufananidzo 4.OR kukoirainhibisa zvakanyanya kuwedzera uremu kweSmCo uye kurasikirwa kwemagineti zvivakwa.

Fig.4 chimiro cheoxidation resistance OR coating paSm2Co17magineti.

"MagnetPower" kubvira ichiita miedzo yekugadzikana kwenguva refu (~ 4000hours) pakupisa kwepamusoro, iyo inogona kupa kugadzikana kwechiratidzo cheSmCo magineti kuitira kushandiswa kwemangwana pakupisa kwakanyanya.

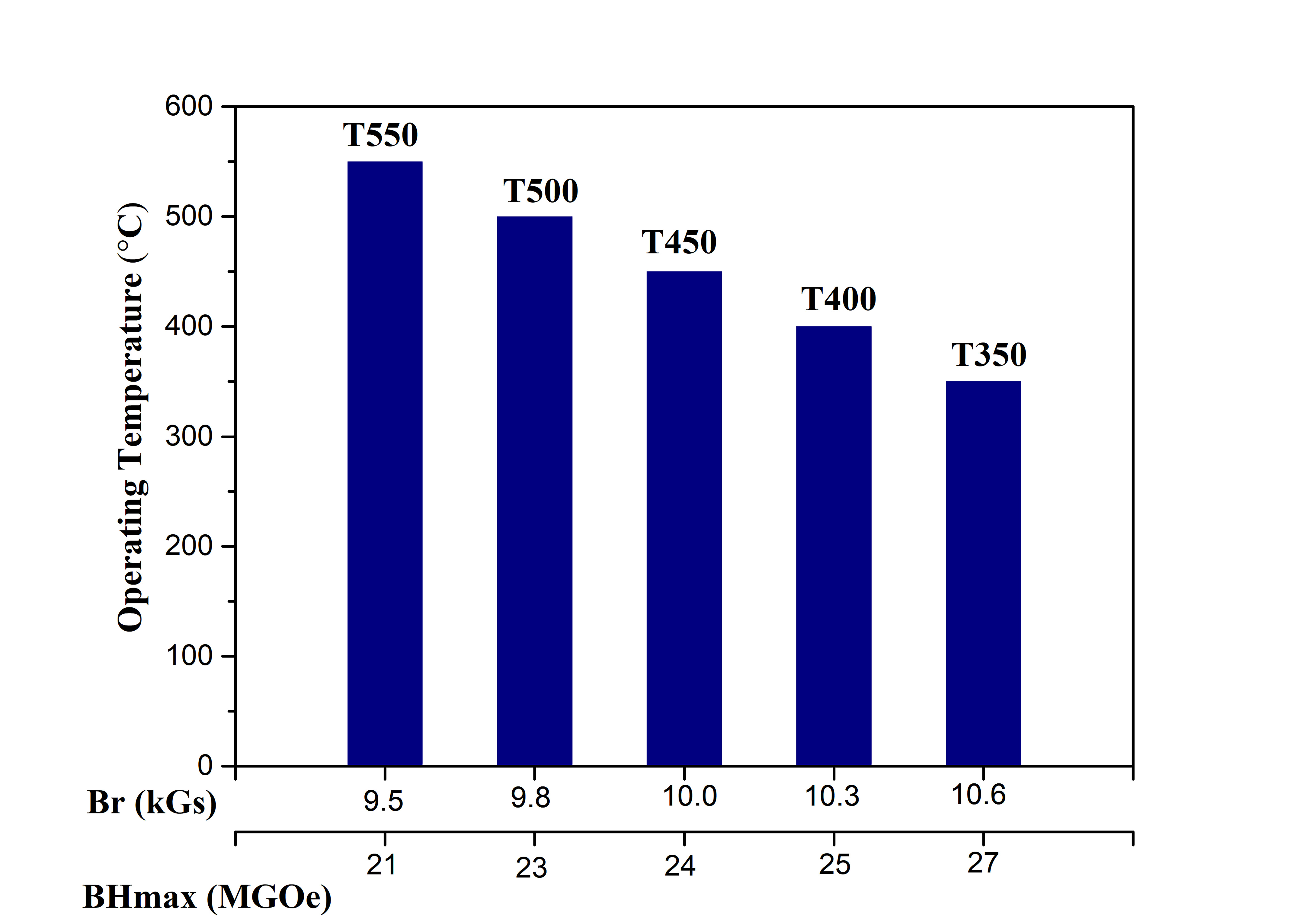

Muna 2021, zvichibva pahukuru hwekushisa kwekushanda chinodiwa, "MagnetPower" yakagadzira nhevedzano yemagiredhi kubva pa350 ° C kusvika 550 ° C .T series).Aya mamakisi anogona kupa sarudzo dzakakwana dzepamusoro-tembiricha yeSmCo application, uye iyo magineti zvimiro zvinobatsira zvakanyanya.Sezvinoratidzwa mumufananidzo 5. Ndokumbira utarise peji rewebhu kuti uwane ruzivo:https://www.magnetpower-tech.com/t-series-sm2co17-smco-magnet-supplier-product/

Fig.5 Iyo yakanyanya tembiricha SmCo magineti (T akatevedzana) ye "MagnetPower"

MHEDZISO

1. Seyakagadzikana zvikuru isingawanzo gineti yepasi, SmCo inogona kushandiswa pakakwirira tembiricha (≥350 ° C) kwenguva pfupi.Iyo yakanyanya tembiricha SmCo (T yakatevedzana) inogona kuiswa pa550 ° C pasina isingachinjiki demagnetization.

2. Zvisinei, kana magineti eSmCo akashandiswa pakupisa kwepamusoro (≥350 ° C) kwenguva yakareba, nzvimbo yacho inowanzoita kubudisa degradation layer.Iko kushandiswa kwe-anti-oxidation coating kunogona kuvimbisa kugadzikana kweSmCo pakupisa kwakanyanya.

Reference

[1] CHCen, IEEE Transactions paMagnetics, 36, 3291-3293, (2000);

[2] JF Liu, Journal of Applied Physics, 85, 2800-2804, (1999);

[3] Shoudong Mao, Chinyorwa cheApplied Physics, 115, 043912,1-6 (2014)

Nguva yekutumira: Jul-08-2023